ENDURANCE E-3120 Active tip brake

No NylOil components

Thanks to our flanged blade connection and introduction of Air Brakes, spring tubes and all troublesome plastic elements, used in original design, have been eliminated!

Air Brakes

Thanks to our deployable blade tips, your turbine will stop safely and gently in any winds utilising areodynamic braking!

Click Here to see it in action!

Improved Generation

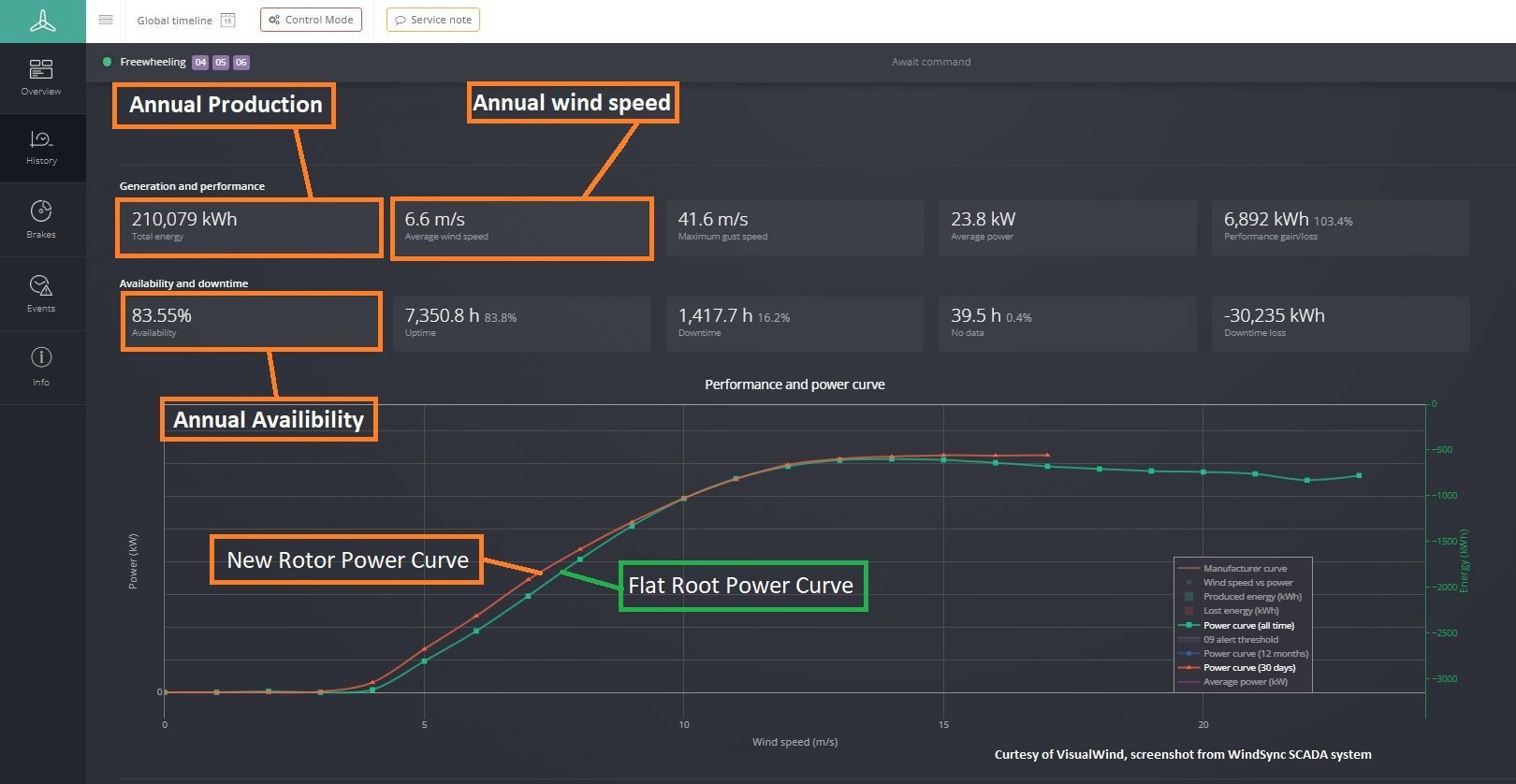

Our new rotor system delivers comparable or even superior power generation capabilities compared to original E-3120 Flat Root Blades. Despite low availibility caused by extensive testing, turbine still produced just over 210.000kWh with 6.6 m/s average wind speed!

Click on the image for full screen

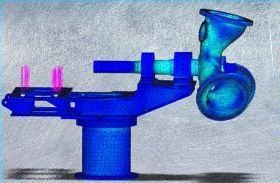

Fully Modelled Nacelle

Our New Rotor system design is based on extensive FEA structural analysis and over 700 Aeroelastic load simulations and in field load and performance tests.

Our Rotor Satystics

Let numbers speak for us:

7

Rotors installed till today

+1.000.000

kWh of generation combined

40+

Years of engineering experiece

0

Breakdowns

"Our Endurance E-3120 wind turbine experienced premature rotor failure after refurbishment (less than 2 years). Fortunately, NorZet, whos founders were part of the design team of the well-regarded Earthmill/Britwind bedplate and shaft upgrade for the E-3120, offered their New Rotor prototype testing on our wind turbine. We are very pleased with the results: improved reliability, increased generation, and the inclusion of tip brakes for enhanced storm protection. We highly recommend NorZet's professionalism and expertise."

James Barlow

Endurance E-3120 turbine owner, Merlin Golf Course, Cornwall

Let’s talk about your project

Contact Us

We will get back to you as soon as possible.

Please try again later.

Follow Us

NorZet Ltd, 71-75 Shelton Street, London, WC2H 2JQ

Company registered in England and Wales 15047030